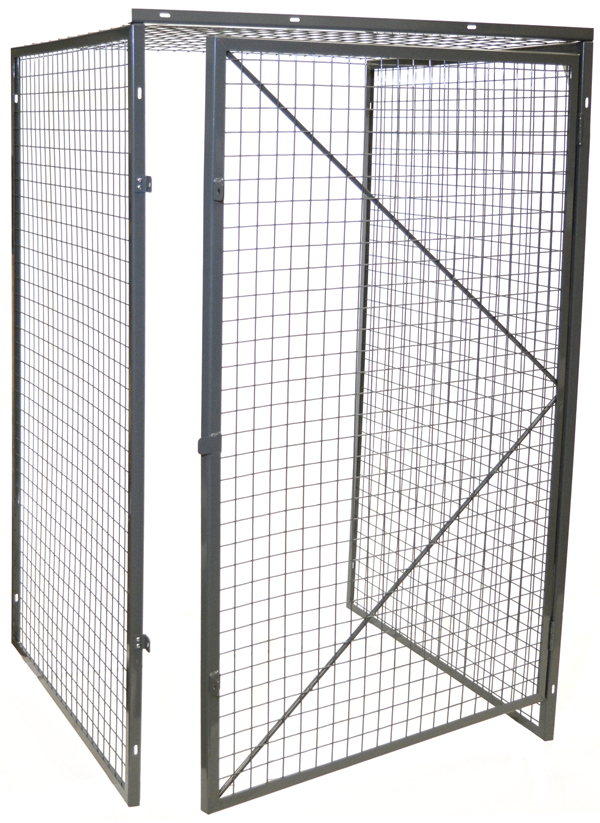

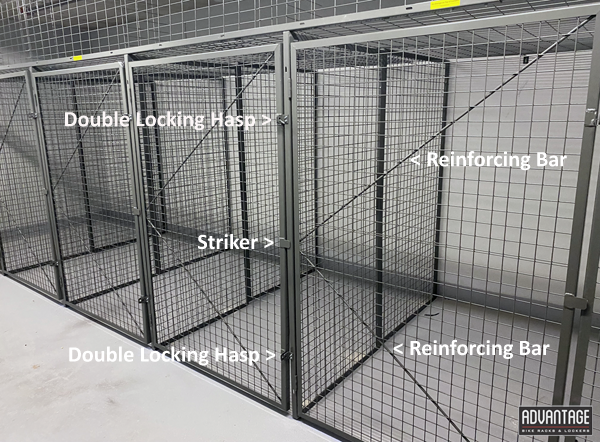

Locker doors begin with the same frame and welded mesh construction as used on our wall panels. We then turn them into doors by adding:

Once locked by the end-user, these doors provide an effective barrier to keep stored good contained and reasonably secure.

For high-end condos and buildings in safety-conscious neighborhoods, our Security Locker product offers enhanced security features and a more robust construction.

Locker ceilings are handled in different ways by different municipalities and building codes.

In Vancouver, per NFPA 13, the ceiling of all lockers can be no taller than 18″ below the sprinkler head.

The ceiling is made of 10ga steel wire mesh sheets welded in a 2″ x 4″ grid to maximize water penetration. These sheets are then wired to the wall panel to maintain future access to the services that commonly run above the lockers.

Wire mesh screen is installed from the top of the locker to the underside of the slab to form a transom barrier. Max. 24″ tall.

Required by many municipalities and inspectors, the goal is to prevent anything from being stored on top of the locker that would interfere with the sprinkler mechanism and/or its’ water coverage in the event of a storeroom fire.

Transom is an important life-safety feature and always best-practice to install. By default, Advantage Lockers include transom.

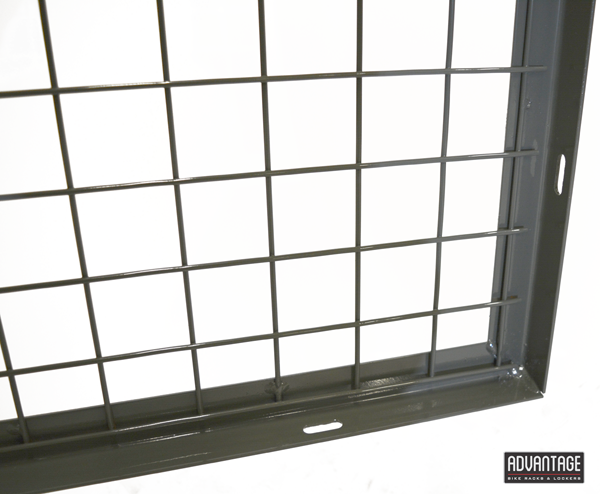

Quality products begin with quality materials.

That’s why Advantage is proud of our long-established relations with all of the top steel and consumables suppliers. Every day, we convert thousands of pounds of:

Our skilled welders then assemble these products into a finished product using top-brand equipment, consumables and specialized welding jigs.

All components are then acid-washed and finished with a baked enamel powdercoat. Our standard colour is RAL7010, a medium grey.

The end-result is a locker built to stand the wear of decades to come.

If your project is located in greater Vancouver, Advantage Lockers provides installation services as well.

Able to tackle even the largest projects, our installers boast years of experience

Advantage works on new residential construction projects only.

If you’re a Owner, Architect or Project Manager, you’re exactly whom we’re here to serve.

A typical project process will run as follows:

Advantage Delivers! Depending on your project, we will either bulk-ship using our flat deck truck, or move product directly to lower levels using our fleet of trade vans.

We understand that construction projects have a lot of moving parts.

To help get our teams installing, we kindly ask Site Supers to ensure that: